SMT DEPARTMENT

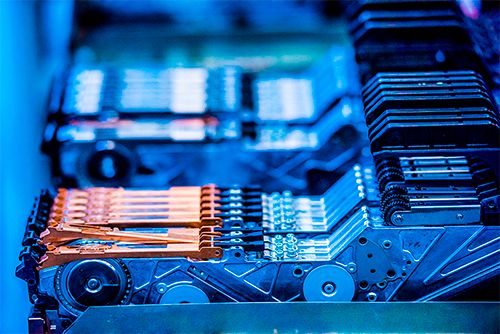

The latest technology and a human team committed to quality and excellence manufacture the most complex products and references on the market.

Our machines allow the assembly of all types of component and PCB format. From the smallest, like 01005, uBGAs, LFPGAs, 0.3mm fine pitch components, and flexible or large scale printed circuit boards.

With a production capacity of 260,000 components per hour, the SMT department has four production lines with the latest machinery:

01005, uBGAs, fine pitch paso 0,3

10 Pick&Place Machines

For the automated assembly of surface-mount components (Yamaha and Assembleon technology).

4 Reflow Ovens

With 9 phases, guaranteeing stability in the various temperature profiles programmed for each product.

4 Screen Printing Machines

Highly configurable with 2D inspection.

4 SPI Machines

Ensuring the quality of the screen printing process with 3D technology.

4 AOI 3D Machines

For optical testing in 3D which are used to inspect the quality of 100% of the cards, revising the soldering, positioning, and components and ensuring production conformity.

2 Flying Probe Machines

These allow in-circuit testing without the need for bed of nails manufacturing.

2 X-Ray Machine

For the inspection of uBGAs, BGAs, LFPGAs, QFNs, and hidden soldering.

Vapor Phase oven

For components with highly complex welds that require a controlled atmosphere in terms of temperature and humidity.