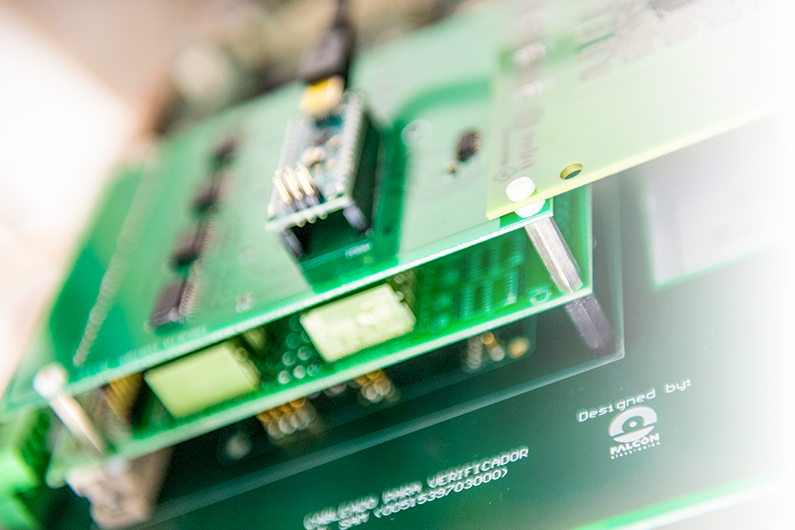

BUILT-IN TESTING

Our research and development division, ELANG ENGINEERING, offers design and manufacturing solutions for test systems, advising our clients on the best possible result and guaranteeing the optimization of and balance between investment in testing, processing time, and the scope of this.

In search of maximum automation.

Traceability management and recording of results.

Connected to the client.

Modular flexibility.

Optimum system combinations.

DESIGN FOR TESTABILITY

With incorporation into the early stages of electronics design and development projects, our experienced professionals visualize and propose two-way strategies to our clients based on which the product should be designed, with a view to testing (DFT) and developing the test required by the product.