NEW PRODUCT LAUNCHES

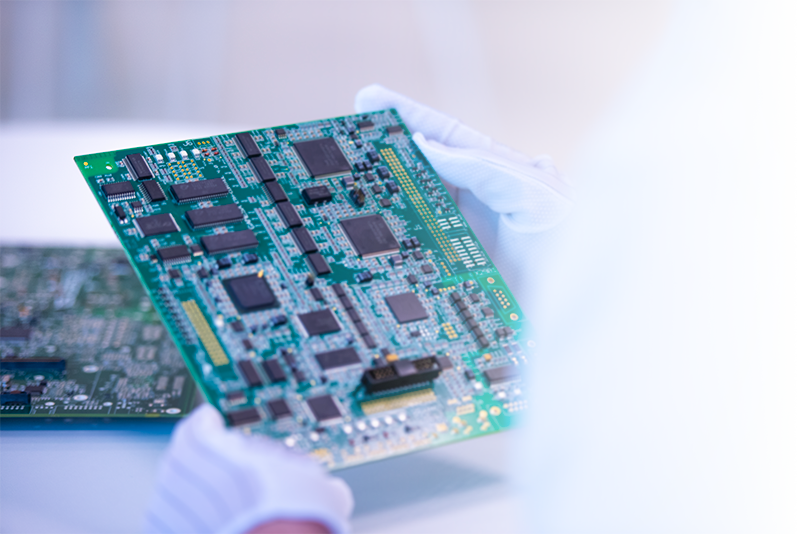

The launching of a new product is a critical phase. During this stage, FALCON ELECTRONICA works to consolidate the product and ensure that it is ready and optimized, before ramping up to mass production.

The products developed from the start of the project with ELANG go through Design audits for excellence (DFX), which consist of Design for Manufacturing (DFM), Design for Provision (DFP), Design for Cost (DFC), Design for Testing (DFT) and Design for Assembly (DFA).

When the product arrives with FALCON ELECTRONICA having been developed externally, the review procedure is performed in a similar way, approaching this from a non-early stage point of view.

Our experienced Product Engineering team, with the collaboration of the other departments involved, directs and coordinates the analyses during the NPI period, reporting regarding options for improvement and any solutions observed before and after the first production batches.